Powering Asia’s power

Since starting operations in Asia Pacific in the early ‘90s, Emerson Process Management Power and Water Solutions has become the technological driver behind the region’s power industry.

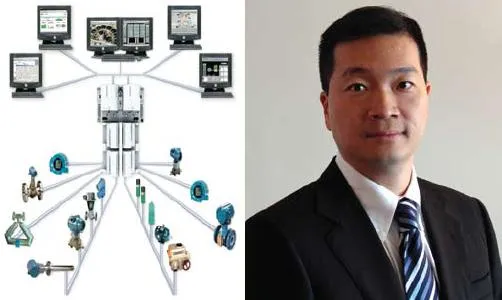

As part of the Emerson Process Management family, the firm’s power and water solutions division merges technology and engineering to bring innovative automation, process management and enterprise integration solutions to the world’s top power utilities. It’s expert control system, Ovation, has emerged as a brand that defines power plant automation and control efficiency and reliability.

At the heart of Emerson’s Plant Web digital plant architecture, Ovation expert control system energizes more than 750 power generation units in some 14 Asia Pacific countries, wielding control over some 220,000MW of generation covering both fossil power and renewable energy plants. It’s “power resume” boasts of a variety of boiler types, steam and gas turbine control systems, and combined cycle, cogeneration and district heating plants.

Andy Wang, Emerson Vice President ,Asia Pacific, talks about Emerson’s role in the region’s power and water industries.

Please tell us more about your products/services currently in the market.

Ovation expert control system is our current DCS product for the power plant automation and controls.

Designed specifically to meet the challenges of the power generation industry, Emerson’s Ovation expert control system offers unique features and functions that a multi-purpose control system just won’t have. Emerson has energized the power industry with revolutionary control solutions for more than 40 years.

Our products and services are backed by our unequaled expertise, and our custom solutions that meet our customer’s unique requirements.

From expert consultant services to world-class technologies, we provide a total I&C solutions for a single unit or entire generating fleet.

Do you also have presence in Water Industry? What are your activities there?

For a quarter of a century Emerson Power & Water Solutions has energized the water and wastewater treatment industries with innovative control solutions built around our Ovation SCADA technology. When municipalities require efficient, constant monitoring and control, they turn to the experts, Emerson.

The very large scale facilities at cities of Chicago, Detroit, San Diego, Sacramento, Washington D.C. and Harbin (China), to name a few, have invested millions in our technology, realizing significant operational cost savings.

How has Emerson’s technology solutions evolved through time? How has this shaped Emerson’s track of growth over the years particularly in Asia?

Emerson is technological leader in the control and automation industry with an accent on delivering top quality solutions that help our customer secure their technology investments. We had been in the centre of some of key technological developments such as PlantWeb, Smart Wireless etc.

These technologies have always helped us keep an edge over our competition at all times. This technological superiority has provided us a leadership position in the power industry all over the world but specially in Asia. In Asia, we have grown tremendously in the last decade. We have major share in newlybuilt power plants in Asia.

China has built many 1000MW Ultrasupercritical (USC) plants which are today’s most advanced coal fired plants in terms of the process and technology.

Significantly, of the 52 units of 1000MW USC plants ordered so far, 32 are using our Ovation expert control technology to control their plants. This clearly shows that when it comes to adopting high end technology, Ovation comes as the first choice.

Do you have any special offerings to help plant owners improve the efficiency of power plant operations?

We have a comprehensive suite of plant optimization software called SmartProcess® which offers adaptive improvement solutions to help utilities achieve optimized equipment performance for emissions compliance, temperature control, efficiency, and overall continuous operational improvement.

SmartProcess incorporates fuzzy logic, neural networks, predictive control, and other tools developed specifically for the needs of our customers to offer the most advanced suite of optimization solutions available. Plantspecific models simulate process variation and changing load levels, so SmartProcess identifies the precise control settings for continuous best performance. The plant model incorporates self-learning features that allow adaptation to long-term changes in the plant.

Emerson’s cutting edge technology solutions has kept clients happy over the years.

Andy notes that around two-thirds of Emerson’s business are repeat customers proof of the high satisfaction rating that Emerson has been receiving over the years.

![Cross Domain [Manu + SBR + ABF + ABR + FMCG + HBR + ]](https://cmg-qa.s3.ap-southeast-1.amazonaws.com/s3fs-public/styles/exclusive_featured_article/public/2025-01/earth-3537401_1920_4.jpg.webp?itok=WaRpTJwE)

![Cross Domain [SBR + ABR]](https://cmg-qa.s3.ap-southeast-1.amazonaws.com/s3fs-public/styles/exclusive_featured_article/public/2025-01/pexels-jahoo-867092-2_1.jpg.webp?itok=o7MUL1oO)

Advertise

Advertise