The perfect power plant solution

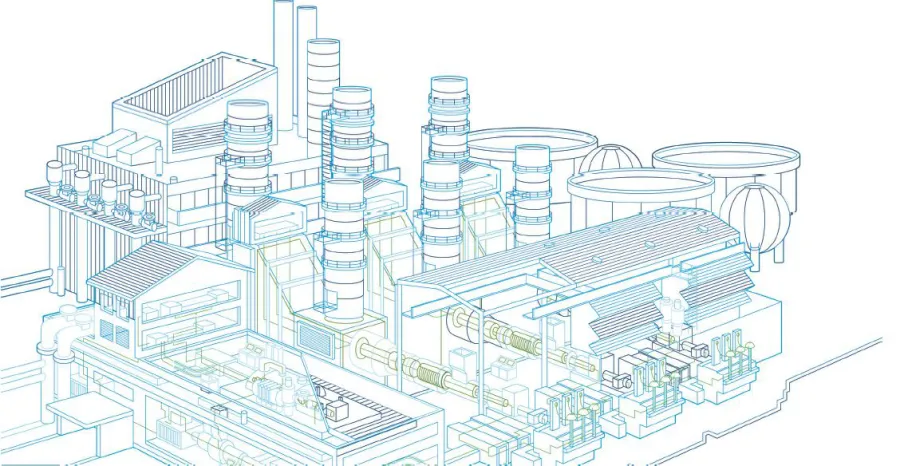

Integrated instrumentation, control and electrical packages for thermal power plants.

ABB has been in the power industry since 1883 – that is a few years longer than the world’s first commercially operated power plants. At that time, we were pioneers in a new and revolutionary industry. Now – 130 years later – we have been in the power generation industry longer than just about any other company. There are few power plants in the world that do not rely on ABB solutions to generate their power and deliver it safely, reliably and efficiently to their customers.

ABB is a market and technology leader in power and automation technologies. We design and manufacture products, systems and solutions for the power and process industries. For the power industry, we deliver complete solutions from power generation to transmission grids and distribution networks. We are the number one supplier in many electrical and control technologies – generator circuit breakers, transformers, substations, motors, drives, gas analyzers, and distributed control systems, to name but a few.

For the power generation sector we integrate these high-performance products into complete instrumentation, control and electrical (ICE) packages for all types of greenfield and brownfield thermal power plants – from super-critical and ultra-supercritical coal-fired plants, to gas- and oil-fired plants, biomass and waste-to-energy plants, and geothermal power plants.

Our scope of supply extends across the entire delivery chain. It begins with system studies and includes detailed design, engineering, project management, installation and commissioning.This incorporates all the electrical, control and instrumentation equipment– from the electrical balance of plant to the substation and grid connection, and from the instrumentation and field devices to the distributed control system.

Integration makes a difference

An integrated solution comprised of products made by ABB has many benefits. The key word is ‘integrated.’ This is where our long and in-depth expertise really does make a difference – both for the EPC (engineering, procurement and construction) contractor and the power plant owner.

For the EPC, it means a single interface with a single vendor, thereby minimizing project risk. It reduces the amount of engineering required and makes it significantly more cost effective. For the end user, it means a more efficient and optimized solution that meets their requirements for availability, redundancy and performance. These benefits are not restricted to any one region. Our global footprint is unsurpassed. ABB operates in around 100 countries worldwide, and has dedicated power generation resources in more than half of those countries. This and our extensive process know-how and experience of local grid codes, gives us a unique capability to help our customers meet their production objectives in whichever country or region they operate.

For instance, in Europe, thermal power plant owners require a high level of operational flexibility to enable power grids to integrate large-scale wind and solar power plants. In India, China and Asia, cost is a market driver – one that ABB is able to meet thanks to its numerous local manufacturing facilities and engineering centers. In the Middle East, our power plant solutions meet the high technical standards and specifications that are required for the region’s demanding climate and operating conditions.

In the Americas, our products and solutions are manufactured locally at ABB factories to meet regional requirements and standards. The heart of ABB’s integrated ICE solutions is the Symphony™ Plus total automation system. This industry-leading control platform integrates all areas of the plant in a simple, scalable, seamless and secure manner. It provides users with the broadest possible view of the plant by integrating data from all plant areas and systems. Through its open architecture, Symphony Plus seamlessly consolidates and visualizes plant data to improve operator response to changing conditions, resulting in improved plant safety

and availability.

Complete service offering

Our service offering covers the complete scope of the plant’s power and automation systems, from the distributed control and plant optimization systems to the instrumentation and emission monitoring systems. On the electrical side, it covers the entire energy path, from electrical balance of plant to the substation and grid connection. We offer a full portfolio of life cycle management services. It extends from repairs and spare parts to complete plant upgrades and equipment retrofits which covers each phase of the plant life cycle, from first concept to decommissioning.

Energy efficiency and plant optimization are two of our specialties. We perform energy efficiency assessments and use our unique process, product and application expertise to identify savings that can reduce plant energy consumption by between 5 and 20 percent.

We also use that same expertise to optimize plant operations with a broad range of solutions, from computer-based maintenance management systems (CMMS) to online optimization tools and online lifetime assessment monitoring for turbines and boilers.

To learn more about ABB’s offering for power plants, contact your local ABB power generation office or go to www.abb.com/powergeneration.

Plug-and-play EBoP solution for new gas power plant in Thailand

ABB is delivering a modular, pre-engineered electrical balance of plant solution for a new gas turbine combined cycle power plant that will help Thailand meet increasing demand for power with more efficient and environmentally sustainable technology. ABB has been awarded a contract from Mitsubishi Heavy Industries (MHI) to design and engineer a complete electrical solution for the 1,600 megawatt (MW) U-Thai gas turbine combined cycle power plant in Thailand. The power plant will be located in the U-Thai district of Ayutthaya Province, about 70 km north of Bangkok.

As part of the solution, ABB is supplying distribution transformers, low and mediumvoltage switchgear as well as direct current (DC) systems. The solution includes a modular and customized E-house to store the electrical equipment that will integrate MHI’s turbine control system. ABB is modular, pre-engineered approach is a cost-effective plug-and-play solution that ensures faster overall delivery. Containers are pre-tested in the factory, helping customers to reduce operational and execution risks, while maintaining the traditional ABB standard of high-quality products and installation.

The U-Thai plant is owned and operated by Gulf JP UT Company, a leading in dependent power producer in Thailand and a subsidiary of Gulf JP Company Limited. Under a 25-year power purchase agreement, the generated electricity will be sold to the Electricity Generating Authority of Thailand (EGAT), and the steam to users in Rojana Industrial Park, serving mainly the electronics and automotive industries.

The plant is part of Thailand’s effort to provide reliable and cost-effective power generation by promoting the use of more efficient and environmentally sustainable technology. More than 80 percent of the country’s power capacity comes from traditional fossil-fuel generation. This project supports Thailand’s public-private partnerships (PPP) program by enhancing the efficiency of its power generation infrastructure, and is in line with the national plan to use such partnerships to add an additional 22 giga watts (GW) to the country’s current 34 GW generating capacity within the decade.

ABB is scheduled to complete its part of the project in the second quarter of 2014. ABB is also currently working with MHI to supply similar electrical equipment and an E-house for the Nong Saeng 1,600 MW gas turbine combined cycle power plant in Thailand’s Saraburi province. This plant is also owned and operated by Gulf JP Company Limited, through its subsidiary, Gulf JP NS Company Limited. The project is currently under construction and scheduled for completion in 2014.

![Cross Domain [Manu + SBR + ABF + ABR + FMCG + HBR + ]](https://cmg-qa.s3.ap-southeast-1.amazonaws.com/s3fs-public/styles/exclusive_featured_article/public/2025-01/earth-3537401_1920_4.jpg.webp?itok=WaRpTJwE)

![Cross Domain [SBR + ABR]](https://cmg-qa.s3.ap-southeast-1.amazonaws.com/s3fs-public/styles/exclusive_featured_article/public/2025-01/pexels-jahoo-867092-2_1.jpg.webp?itok=o7MUL1oO)

Advertise

Advertise