The Black Point Power Station gas supply project

Castle Peak Power Company Limited, Hong Kong (CAPCO). A joint venture between ExxonMobil Energy Ltd. and CLP Power Hong Kong Ltd.

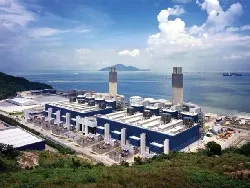

Black Point Power Station (BPPS) was the first natural gas-fired power generation facility in Hong Kong. Its eight single-shaft units were put into service in phases from 1996 to 2006, and with 2,500MW of installed capacity, it is one of the largest gas-fired combined cycle stations in the world.

The facilities at Black Point were originally designed to burn gas from one dedicated source, the Yacheng 13-1 gas field in the South China Sea. That supply is now rapidly depleting, and the Station must be prepared for a transition to new sources of gas.

In 2008, the Hong Kong and Central governments signed a Memorandum of Understanding to provide Hong Kong with natural gas from different new sources.

The first source to go live is the Second West-East Natural Gas Pipeline. Spanning nearly 9,000 kilometres, it is the world’s longest natural gas pipeline passing through 14 different provinces and regions of China. The natural gas from Turkmenistan in Central Asia is then brought all the way through China to the Pearl River Delta, reaching Shenzhen, and then be sent along a branch line to BPPS in Hong Kong.

The multiple new gas supplies will have different qualities from the current source and, similar to issues faced in other parts of the world, the gas qualities may vary more widely from what the installed equipment is designed for use. In order to make the transition, the Station required major enhancements to enable it to manage a diverse portfolio of future gas sources.

The Project’s objective is to upgrade the Station with new gas receiving and gas conditioning systems. The enhancements give the operators flexibility to utilize multiple gas sources concurrently even when each source may have a substantially different and variable gas quality.

A new Gas Receiving Station (GRS) has been built to provide a second inlet for gas at BPPS. It adjusts the temperature and pressure of the secondary gas stream to match the primary gas inlet.

This facility has a large turndown ratio, which maximizes the operator’s ability to select the desired proportions of gas to be received from each inlet. Gas from the new GRS is then conveyed via a second, parallel distribution system to the eight power generation units.

Each power generation unit is being retrofitted with a dynamic Fuel Quality Management System (FQMS). The FQMS reads incoming gas quality data and uses a heater to correct the combustion properties of the gas in real time just upstream of the gas turbine.

In conjunction with new turbine hardware and control system upgrades, this modification enables each generation unit at the Station to regulate and moderate the dynamic changes in its gas specification that otherwise might push it outside normal operating range.

Finally, two of the Station’s eight generation units are being upgraded with facilities that will allow operators to blend gas from both the old and new GRS and send the mixed stream to the gas turbine. Along with the FQMS to manage the combustion properties, this modification allows the Station even finer control over gas source utilization.

When work is completed in 2013, the Gas Supply Project will have enabled BPPS to operate with a broad portfolio of concurrent gas supplies, each of which may have different and variable quality specifications.

It will be successfully putting into operation a unique combination of technologies that allows the Station to source a wide range of gases and presents a new benchmark in operational flexibility for managing multiple gas sources at a gas-fired power station.

![Cross Domain [Manu + SBR + ABF + ABR + FMCG + HBR + ]](https://cmg-qa.s3.ap-southeast-1.amazonaws.com/s3fs-public/styles/exclusive_featured_article/public/2025-01/earth-3537401_1920_4.jpg.webp?itok=WaRpTJwE)

![Cross Domain [SBR + ABR]](https://cmg-qa.s3.ap-southeast-1.amazonaws.com/s3fs-public/styles/exclusive_featured_article/public/2025-01/pexels-jahoo-867092-2_1.jpg.webp?itok=o7MUL1oO)

Advertise

Advertise